Clamshell / Blister

Packaging Equipment

- Home

- our solutions

- Clamshell / Blister Packaging Machines

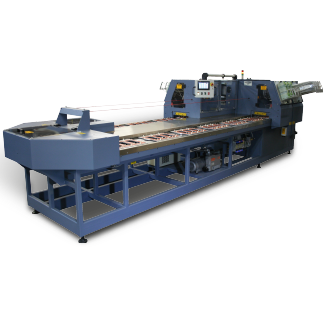

Starview’s Fully Automatic Clamshell Sealing Machine

Increase the output of your clamshell packaging line with Starview's PHS8A-1418. Decrease labor cost by automatically feeding all your packaging materials, sealing and unloading with this market leading clamshell sealing machine. Fast, efficient change-over with all quick-change tooling allows you to switch from one size package to the next in less than 30 minutes. The PHS8A-1418 will also automatically feed and seal standard blister packaging materials.

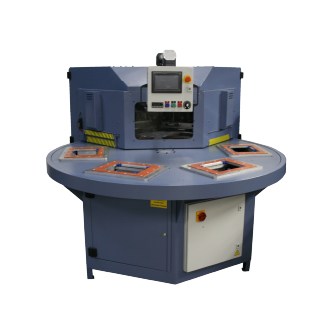

take a look at PHSA seriesStarview’s Semi-automatic Rotary Hot/Cold Clamshell & Blister Packaging Machines

Starview’s PHS Series rotary type Clamshell and Blister sealers are designed for medium to higher volume production requirements. These machines may be used for Plastic-to-Plastic Clamshell sealing as well as conventional carded blisters, full face blisters and half-clamshell styles including applications using Tyvek, foils and other heat sealable lidstock.

learn more about PHS series

PHS SERIES

Semi-Automatic Rotary |

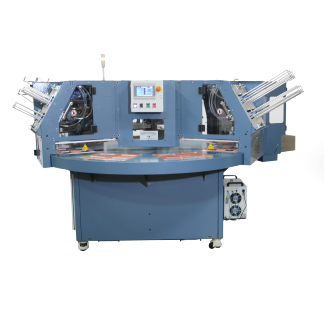

PHSA series

Fully Automatic Rotary |

BSC II Series

Fully Automatic Carousel |

|

| Size type of production: | medium to high plastic to plastic | high volume | high volume |

| Nominal sealing area: | 14” x 18” / 18” x 24“ | 14” x 18” / 18” x 24“ | 14” x 18” / 18” x 24“ |

| Open loading stations: | 1 to 5 | 2 | 7 |

| Max. blister depth: | 3.0” | 3.0” | 3.0” |

| Max. clamshell back height: | 1.25” to 2” | 1.5” to 2” | 2.5” |

| Clamshell front feeder: | N/A | Standard | Standard |

| Clamshell Card feeder: | N/A | Standard | Standard |

| Finished package unloader: | Optional | Standard | Standard |

| Avg. cycle speed clamshell pkg: | 1-12 cpm | 1-12 cpm | 1-12 cpm |

| Avg. cycle speed blister pkg: | 3-15 cpm | 3-15 cpm | 3-15 cpm |